Audience: |

Beginner to Advanced |

|

|

Schedule: |

Days 1-4: 7:30 AM – 6:30 PM MSTDay 5: 7:30 AM – 11:00 AM MST |

||

| This course is certified by Probitas Authentication. Successful completion of this course satisfies the AS9110 Lead Auditor training requirement for Aerospace Auditor authentication.

Even though AS9110 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard. In addition to this course, aerospace auditors must also complete the IAQG sanctioned Aerospace Auditor Transition Training course to fulfill the training requirements for aerospace auditor authentication and recognition in OASIS. |

|||

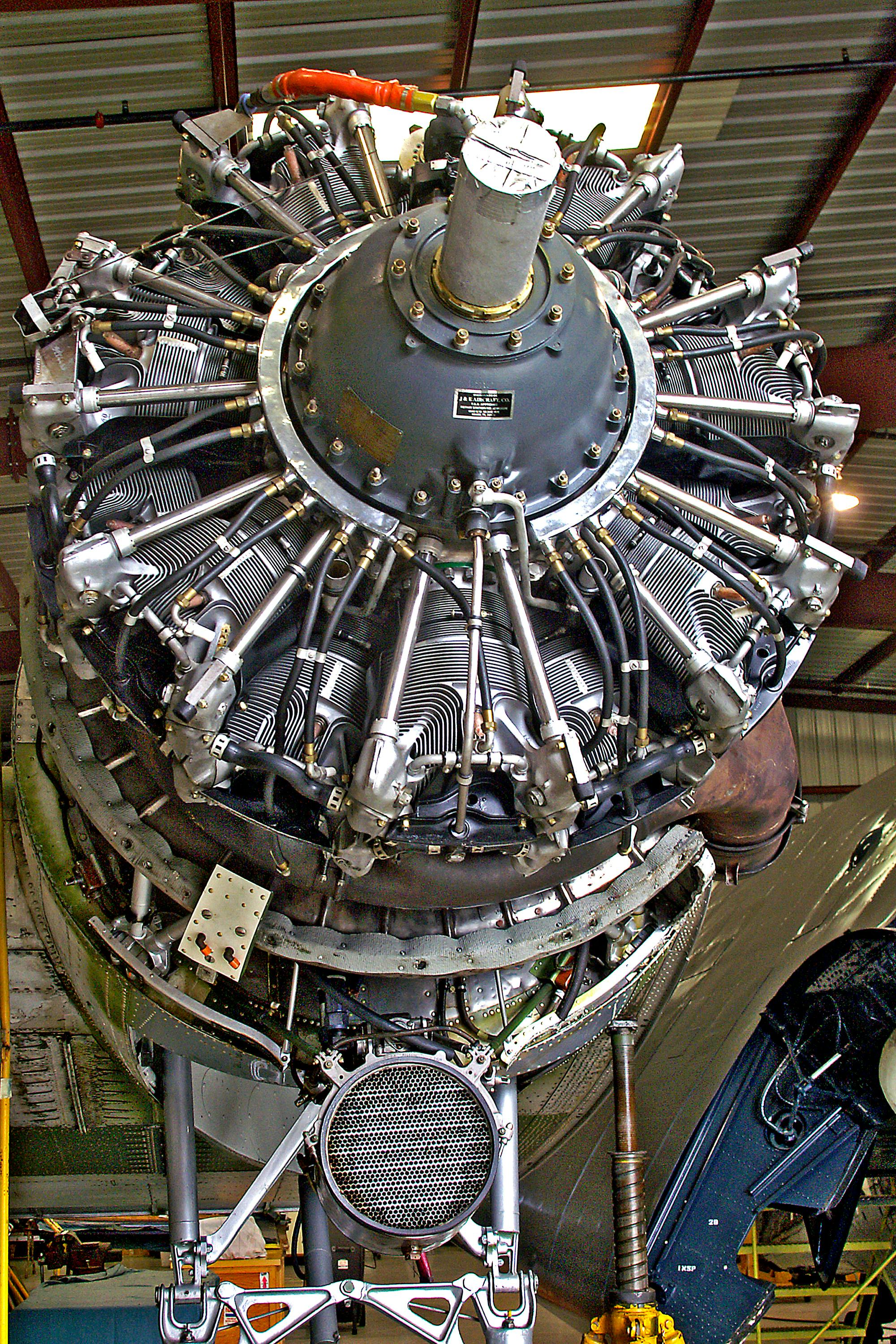

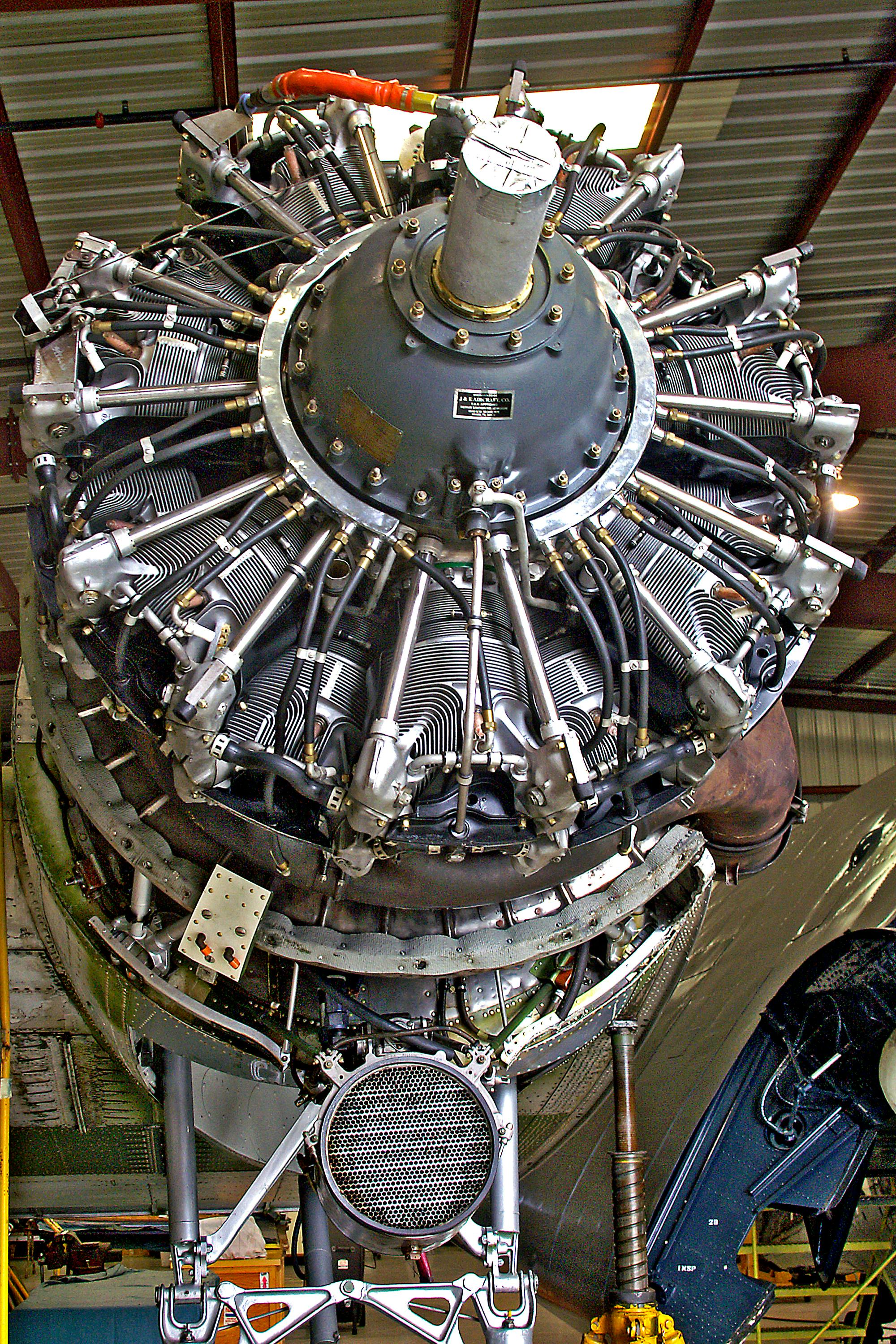

OverviewOrganizations in the aerospace maintenance, repair, and overhaul (MRO) industry face unique quality requirements, and effective auditing is essential for maintaining compliance, managing risk, and ensuring safety. AS9110 builds on ISO 9001 by adding MRO-specific requirements that must be clearly understood and properly assessed during audits. This interactive, live-online AS9110 Lead Auditor Training equips you with the knowledge and practical skills to conduct, manage, and lead audits to both AS9110C and ISO 9001:2015 standards. Certified by Probitas, this course fulfills the formal training requirement for AS9110 Lead Auditors. Led by experienced instructors, you will explore every phase of the audit process, including:

This course emphasizes hands-on learning through interactive activities, group discussions, case studies, real-world scenarios, and role-playing exercises. Whether you are auditing internal processes, suppliers, or regulatory compliance, you will gain the confidence, knowledge, and tools needed to perform high-quality audits in MRO and aerospace service environments. You will also leave with a practical, structured, and repeatable approach to auditing that supports long-term success. |

Pre-RequisitesStudents will need to complete assignments before the start of class, including reading the standard. This AS9110 Lead Auditor training course is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own copy of the AS9110 RevC standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| AS9100 Rev D Lead Auditor Training | AATT AS9100 IAQG Sanctioned Aerospace Auditor Transition Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

Audience: |

Beginner to Advanced |

|

|

Schedule: |

7:30 AM – 6:30 PM MST |

||

| Axeon Inc. is certified by Probitas Authentication and is an IAQG recognized Training Provider for the AS9110 Lead Auditor Training Class. This AS9110 Internal Auditor Class is certified by Axeon, Inc. | |||

OverviewOrganizations in the aerospace maintenance, repair, and overhaul (MRO) industry operate in an environment where safety, airworthiness, and regulatory compliance are non-negotiable. Internal audits are not just a requirement, they are a critical tool for managing risk, preventing escapes, and strengthening operational control. AS9110 builds on ISO 9001 by adding MRO-specific requirements that must be clearly understood, correctly interpreted, and effectively audited to ensure your Quality Management System truly supports safe and reliable operations. This interactive, live-online AS9110 Internal Auditor Training is designed to prepare you to confidently conduct internal audits to AS9110:2016 Rev C. Delivered by an IAQG-recognized training provider through Probitas Authentication, this course focuses on building real-world auditing competence, not just theoretical knowledge. Led by experienced aerospace auditors, this practical 3-day course walks you through every phase of the internal audit process, including:

Unlike academic programs that emphasize abstract quality theory, this course is hands-on and application-driven. Through case studies, group discussions, real-world scenarios, quizzes, and role-playing exercises, you will actively practice the skills needed to perform effective internal audits in MRO and aerospace service environments. By the end of the course, you will be prepared to conduct a structured, thorough, and value-added internal audit that not only verifies compliance, but drives meaningful improvement within your Quality Management System. |

Pre-RequisitesStudents will need to complete assignments before the start of class, including reading the standard. This AS9110 Internal Auditor training course is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own copy of the AS9110 RevC standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| AS9110 Lead Auditor Training | AS9100 Rev D Lead Auditor Training | AATT AS9100 IAQG Sanctioned Aerospace Auditor Transition Training | AS9145 APQP & PPAP Training |

Audience: |

Beginner to Advanced |

|

|

Schedule: |

Days 1-4: 7:30 AM – 6:30 PM Local TimeDay 5: 7:30 AM – 11:00 AM Local Time |

||

| This course is certified by Probitas Authentication. Successful completion of this course satisfies the AS9110 Lead Auditor training requirement for Aerospace Auditor authentication.

Even though AS9110 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard. In addition to this course, aerospace auditors must also complete the IAQG sanctioned Aerospace Auditor Transition Training course to fulfill the training requirements for aerospace auditor authentication and recognition in OASIS. |

|||

OverviewIn the aerospace maintenance, repair, and overhaul (MRO) industry, compliance with AS9110C and ISO 9001:2015 is critical to ensuring quality, safety, and customer satisfaction. Auditors must be well-prepared to assess both general and MRO-specific requirements with precision and confidence. This in-person AS9110C Lead Auditor Training delivers a rich, immersive learning experience that goes beyond the screen. Certified by Probitas, this five-day course fulfills the formal training requirement for AS9110 Lead Auditors and equips you with the practical skills needed to conduct, manage, and lead internal, supplier, and regulatory audits. Held in a traditional classroom setting, this training allows for deeper engagement, real-time feedback, and dynamic peer interaction. You’ll benefit from direct access to instructors, group exercises, and collaborative discussions that mirror the challenges auditors face in the field. In this class, you will explore every phase of the audit process, including:

This course is highly interactive, using case studies, role-playing scenarios, and real-time coaching to build your competence and confidence. The in-person format enhances retention, fosters professional connections, and provides a hands-on environment ideal for building strong audit leadership skills. Whether you are advancing your career or supporting your organization’s certification goals, this training offers the structure, support, and in-depth instruction you need to succeed. |

Pre-RequisitesStudents will need to complete assignments before the start of class, including reading the standard. This AS9110C Lead Auditor training course is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own copy of the AS9110C standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| AS9100 Rev D Lead Auditor Training | AATT AS9100 IAQG Sanctioned Aerospace Auditor Transition Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

Schedule: |

Online: 10-15+ hours

Instructor-led: 4 days |

|

|

Languages: |

English (other IAQG-approved languages to be released separately) | ||

| Axeon is certified by Probitas Authentication and is an IAQG recognized Training Provider. This course is certified by the IAQG, and successful completion of this course satisfies the Aerospace Auditor Transition Training requirement for AS9100 Aerospace Auditor authentication.

The IAQG-sanctioned 9100:2016 AATT has been mandated by the IAQG to satisfy the Foundation Course training requirement for 9100:2016 AQMS auditor authentication. The 9100 Online Component includes the ISO 9001:2015 Pre-Assessment, Foundations: Understanding AS9100 Online Training, 9100:2016 Forms and Audit Reporting Training, and Trial Assessment Scenario 1 and 2. The four-day instructor-led portion of the AATT training focuses on applying the 9100:2016 requirements in audit situations using 9101:2022 forms and in consideration of 9101:2022 requirements. The fourth day of the instructor-led course is reserved for the final examination. Refer to the “Program Overview” section below for more information. NOTE: This item includes the 9100 Online Component and the 9100 Instructor-Led Training. You will be contacted by an Axeon representative to finalize registration. |

|||

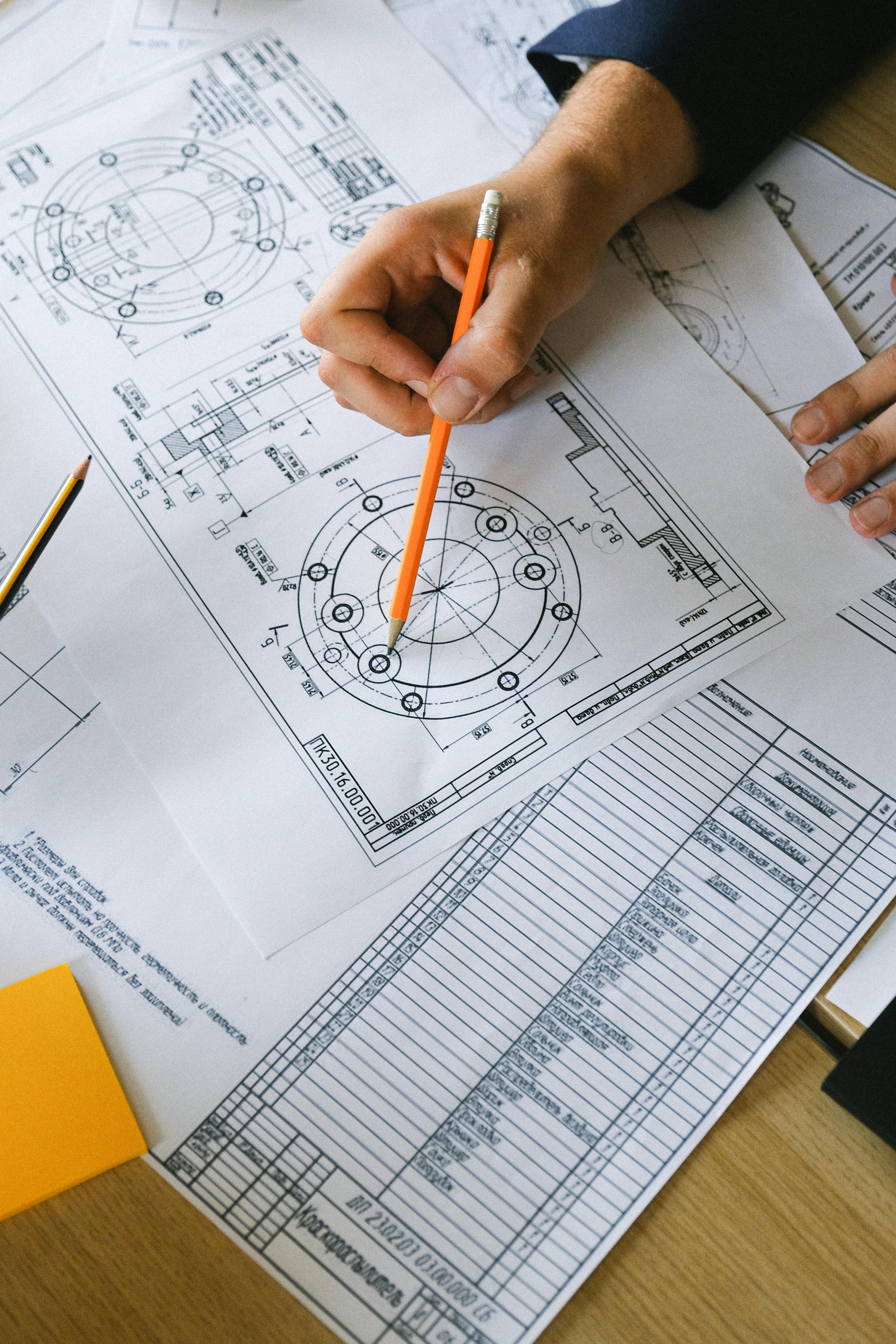

Program OverviewThere are both optional and required modules and classes to complete the AATT program. Required online modules must be completed before attending the instructor-led training. The online modules identified as optional are highly recommended, but not required. In the case of Trial Assessment Scenario 2, participants are encouraged to wait until the instructor-led training portion of the AATT (day 3) is completed before attempting this module. AATT Prep Class (Optional)The national pass rate for the AATT class is only about 30%. At Axeon, our pass rate is about 70%. This one-day preparatory class is a game changer. It will prepare you for the AATT class, greatly increasing the amount you learn during the AATT and help you to pass the tests. It is much more than simply a refresher of the AS9100 and AS9101. All students, no matter what their experience will benefit from this class and will have a much higher likelihood of passing the AATT. ISO 9001:2015 Pre-Assessment (Required)Evaluation to assess the trainees’ knowledge of specific changes in the ISO 9001:2015 standard. You are required to achieve an overall score of 80% to pass this assessment. This assessment is divided into two sections:

Foundations: Understanding 9100 Online Training (Required)This is a prerequisite to attend the Aerospace Auditor Transition Training (AATT) and will help you develop the following competencies:

9100 Forms and Audit Reporting Training (Required)The purpose of this training is to address the requirements of 9100:2016, in the context of a third-party audit, considering the use of 9101:2022 forms and the conformity with 9101:2022 requirements. Trial Assessment Scenario 1 and 2 & Review (Optional)Each Trial Assessment scenario consists of a single 20-minute scenario with three question screens. The scenario asks you to evaluate audit evidence and make decisions based on your understanding of 9101:2022 and your ability to use the 9101:2022 forms. Once you complete the scenario, you will be taken to the Trial Assessment Scenario Review module, where the correct answers will be explained along with the rationale. |

Pre-RequisitesTraining and Entry Knowledge

Standard Documents

Online Training (9100 Online Component)

|

|

Who Should Attend

|

Successful completion of the 9100 AATT requires that you achieve a passing score on both the Knowledge and Application Examinations.

Failure to achieve the required score on the Knowledge Examination will require a full knowledge retake.

Your score for the application section is the combined result of your online application exam (2 hours), interview, and the continuous evaluation during the training class (which includes written reports and oral communication of conclusions regarding the case study material). If the auditor score is:

The online application retake is 2 hours in length and follows the same structure of the final application examination on the 4th day of the training. This retake must be completed in a proctored environment. If the score is lower than 80%, another retake can be done, up to a maximum of two times. Two failures on the application retake will require applying to the entire four-day training again.

Those who pass will receive a certificate of successful completion that satisfies the Foundations training course requirement for AA/AEA authentication through an approved AAB.

| AS9100 Rev D Lead Auditor Training | AS9110 Lead Auditor Training | Prep Class for Aerospace Auditor Transition Training (AATT) | AS9145 APQP & PPAP Training |

Note:

OverviewIf you want to become a third-party aerospace auditor for AS9100, AS9110, or AS9120, you’ll need to complete the Aerospace Auditor Transition Training (AATT). This course is required by Probitas Authentication and recognized by the International Aerospace Quality Group (IAQG). It’s a key step toward certification but also one of the most difficult. Many students take the AATT to advance their careers and meet personal goals. But the course is challenging, and the national pass rate is only about 30%. That’s why this one-day prep class is such a valuable investment. It lays the foundation you need to succeed in the AATT and helps you get more out of the training. This isn’t just a refresher on AS9100 and AS9101. Whether you’re new to aerospace auditing or already have experience, this class sharpens your understanding of the standards, clarifies what to expect in the AATT, and gives you practical strategies to pass the exams. And it works. Students who take Axeon’s prep class have a much higher than average pass rate. With Axeon’s proven approach, you’ll go into the AATT more confident, more prepared, and with a much greater chance of success. |

PrerequisitesThis class is scheduled a week before the AATT AS9100 IAQG Sanctioned Aerospace Auditor Transition Training in order to help students prepare for the class and, ultimately, the exam. In order to attend this class, you must have completed the prerequisites for the AATT course. So you must have passed either the AS9100 or AS9110 Lead Auditor Training. |

|

Who Should Attend

|

| AS9100 Rev D Lead Auditor Training | AS9110 Lead Auditor Training | AATT AS9100 IAQG Sanctioned Aerospace Auditor Transition Training | AS9145 APQP & PPAP Training |

Audience: |

Beginner to Advanced |

|

|

Schedule: |

Days 1-4: 7:30 AM – 6:30 PM MSTDay 5: 7:30 AM – 11:00 AM MST |

||

| This course is certified by Probitas Authentication. Successful completion of this course satisfies the Lead Auditor training requirement for AS9100 Aerospace Auditor authentication. | |||

OverviewIn today’s competitive aerospace industry, ensuring compliance with AS9100 standards is critical for maintaining quality, meeting customer expectations, and securing contracts. Effective auditing is the foundation of a robust Quality Management System (QMS), and skilled auditors are in high demand to help organizations achieve and sustain excellence. This interactive, live-online AS9100 lead auditor training course equips you with the knowledge and skills to conduct effective QMS audits in line with AS9100 Rev D and ISO 9001:2015 standards. You’ll learn how to interpret the verbiage of the standards and apply them to your own organization. Guided by expert instructors, you’ll explore every phase of the audit process, including:

Our training includes easy-to-use tools to streamline the auditing process, ensuring you succeed regardless of your experience level or career stage. This practical AS9100 lead auditor training course is designed to engage and empower participants. Through interactive case studies, role-playing scenarios, and other real-world exercises, you’ll not only deepen your understanding of auditing principles but also build confidence to apply them effectively in any setting. |

Pre-RequisitesThere are no required prerequisites for this training. This AS9100 Lead Auditor training course is beneficial for both quality novices and lifetime professionals. All students are required to bring their own printed copy of the AS9100 RevD standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| AS9100 Rev D Internal Auditor Training | AS5553 & AS6174 Counterfeit Parts Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

Audience: |

Beginner to Advanced |

|

|

Schedule: |

Days 1-4: 7:30 AM – 6:30 PM Local TimeDay 5: 7:30 AM – 11:00 AM Local Time |

||

| This course is certified by Probitas Authentication. Successful completion of this course satisfies the Lead Auditor training requirement for AS9100 Aerospace Auditor authentication. | |||

OverviewIn today’s competitive aerospace industry, ensuring compliance with AS9100 standards is critical for maintaining quality, meeting customer expectations, and securing contracts. Effective auditing is the foundation of a robust Quality Management System (QMS), and skilled auditors are in high demand to help organizations achieve and sustain excellence. This interactive, in-person AS9100D lead auditor training course equips you with the knowledge and skills to conduct effective QMS audits in line with AS9100D and ISO 9001:2015 standards. You’ll learn how to interpret the verbiage of the standards and apply them to your own organization. Guided by expert instructors, you’ll explore every phase of the audit process, including:

Our training includes easy-to-use tools to streamline the auditing process, ensuring you succeed regardless of your experience level or career stage. This practical AS9100 lead auditor training course is designed to engage and empower participants. Through interactive case studies, role-playing scenarios, and other real-world exercises, you’ll not only deepen your understanding of auditing principles but also build confidence to apply them effectively in any setting. |

Pre-RequisitesThere are no required prerequisites for this training. This AS9100 Lead Auditor training course is beneficial for both quality novices and lifetime professionals. All students are required to bring their own printed copy of the AS9100D standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| AS9100D Internal Auditor Training | AS5553 & AS6174 Counterfeit Parts Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

Audience: |

Beginner to Advanced |

|

|

Schedule: |

7:30 AM – 6:30 PM MST |

||

| This course is certified by Probitas Authentication. | |||

OverviewIn today’s fast-paced aerospace industry, maintaining AS9100 compliance is crucial for ensuring quality, meeting customer expectations, and remaining competitive. A well-executed internal audit strengthens an organization’s Quality Management System (QMS), making trained internal auditors an invaluable resource. This interactive, live-online AS9100 ISO 9001 internal auditor training equips you with the essential skills and knowledge to conduct effective audits in line with AS9100 and ISO 9001:2015 requirements. You’ll learn how to interpret key standards and apply them within your organization to drive continuous improvement. Taught by expert instructors in a dynamic virtual classroom, this course covers every phase of the internal audit process, including:

Through engaging discussions, virtual role-playing scenarios, and real-world case studies, you’ll gain practical experience and confidence in auditing techniques—no matter your experience level or industry background. By the end of this course, you’ll have the tools and expertise to perform internal audits that enhance compliance, improve processes, and contribute to organizational success—all from the convenience of your home or office. |

PrerequisitesThere are no required prerequisites for this training. This AS9100 internal auditor training course is beneficial for both quality novices and lifetime professionals. All attendees are required to bring their own copy of the ISO 9001:2015 or AS9100:2016 Rev D Quality Management Standard Requirements for this training course. These will not be provided for you. We strongly advise you bring a paper copy or an electronic copy that allows you to take notes for your AS9100 ISO 9001 auditor training. |

|

Who Should Attend

|

| AS9100D Lead Auditor Training | AS5553 & AS6174 Counterfeit Parts Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

Audience: |

Beginner to Advanced |

|

|

Schedule: |

7:30 AM – 6:30 PM Local Time |

||

| This course is certified by Probitas Authentication. | |||

OverviewIn today’s highly competitive aerospace industry, ensuring compliance with AS9100 standards is essential for maintaining quality, meeting customer requirements, and staying ahead of the competition. A strong Quality Management System (QMS) relies on effective internal audits, making skilled internal auditors a valuable asset to any organization. This hands-on, in-person AS9100D auditor training course is designed to provide you with the knowledge and tools needed to perform and participate in effective audits in accordance with AS9100D and ISO 9001:2015 standards. You’ll gain a clear understanding of how to interpret the requirements and apply them within your organization. Led by experienced instructors, this course guides you through all stages of the internal audit process, including:

You’ll also receive practical tools to simplify the auditing process, ensuring success no matter your experience level or career stage. This engaging AS9100 auditor training course combines real-world exercises, role-playing scenarios, and interactive discussions to reinforce your understanding of audit principles. By the end of the course, you’ll be equipped with the confidence and skills to conduct internal audits that support continuous improvement and organizational success. |

PrerequisitesThere are no required prerequisites for this training. This AS9100 auditor training course is beneficial for both quality novices and lifetime professionals. All attendees are required to bring their own copy of the ISO 9001:2015 or AS9100:2016 Rev D Quality Management Standard Requirements for this training course. These will not be provided for you. We strongly advise you bring a paper copy or an electronic copy that allows you to take notes for your ISO 9001 and AS9100 auditor training. |

|

Who Should Attend

|

| AS9100D Lead Auditor Training | AS5553 & AS6174 Counterfeit Parts Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

OverviewIn the aerospace and defense industry, internal audits are more than just a compliance requirement. They are a strategic tool for improving processes, ensuring product quality, and meeting the demanding expectations of customers and regulators. AS9100 internal auditors play a key role in helping organizations maintain certification and stay competitive in a highly regulated market. This two-day, live-online AS9100 Internal Auditor training course—integrated with ISO 9001:2015—gives you the skills and knowledge to perform internal audits with confidence. Whether you are new to auditing or need a structured refresher, this course will help you interpret the requirements of AS9100 Rev D and ISO 9001:2015 and apply them in real-world audit scenarios. Guided by experienced instructors, you’ll cover each stage of the internal audit process:

This AS9100 Internal Auditor training course emphasizes practical learning. Through hands-on exercises, case studies, and realistic audit simulations, you will build the skills needed to conduct effective, value-added audits. The training avoids unnecessary theory and focuses instead on what internal auditors truly need to know and do on the job. Delivered entirely online in a live, instructor-led format, this course offers a flexible and engaging way to strengthen your internal audit capabilities without stepping away from your day-to-day responsibilities. |

Pre-RequisitesThere are no required prerequisites for this training. This AS9100 Internal Auditor training course is beneficial for both quality novices and lifetime professionals. All students are required to bring their own printed or virtual copy of the AS9100 Rev D standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| ISO 9001 Lead Auditor Training | AS9100 Lead Auditor Training | Root Cause Analysis & CAPA Training | AS9102 First Article Inspection Training |

OverviewIn medical device and manufacturing industries, design controls are more than just a regulatory requirement. They form the foundation for developing safe, effective, and reliable products that meet customer needs while complying with global standards. Organizations that manage design controls effectively not only maintain compliance but also reduce risks, avoid costly redesigns, and ensure smooth product launches. This two-day Design Control Training course, aligned with ISO 9001:2015, ISO 13485:2016, FDA 21 CFR 820 (QMSR), and EU MDR 2017/745, gives you the skills and knowledge to implement, manage, and audit design and development activities with confidence. Whether you are new to design controls or seeking a structured refresher, this course will help you interpret the requirements and apply them in real-world scenarios. Guided by experienced instructors, you will cover each stage of the design and development process:

This training emphasizes practical application over theory. Through hands-on activities, case studies, and interactive discussions, you will build the skills needed to integrate design controls into your Quality Management System and prepare for audits and regulatory inspections. Delivered in a live, instructor-led format, this course offers an engaging and flexible way to strengthen your design and development expertise without stepping away from your day-to-day responsibilities. |

Pre-RequisitesOur goal is to meet everyone at their current level and increase it. Medical Device students should review the ISO 13485:2016 Standard Clause 7.3 and 21 CFR 820.30 to prepare for class. General Manufacturing students should review ISO 9001:2015 Clause 8.3 to prepare for class. By reviewing these materials before class, you will come in aware of the content of the standards and be ready to learn how to apply them. |

|

Who Should Attend

|

| ISO 13485 Lead Auditor Training | ISO 9001 Lead Auditor Training | Root Cause Analysis & CAPA Training | EU Medical Device Regulation (EU MDR) Training |

OverviewIn today’s fast-paced business environment, organizations must ensure compliance with ISO 9001:2015 to maintain quality, enhance efficiency, and stay competitive. Effective auditing is the backbone of a strong Quality Management System (QMS), and skilled lead auditors play a critical role in driving continuous improvement. This interactive, live-online ISO 9001 Lead Auditor Training equips you with the knowledge and practical skills to conduct, manage, and lead audits with confidence. Recognized by Exemplar Global, this course prepares you to interpret ISO 9001 requirements, assess compliance, and drive meaningful improvements in any organization. Guided by expert instructors, you’ll explore every phase of the audit process, including:

This hands-on ISO 9001 lead auditor training program is designed to actively involve and equip participants with essential auditing skills. By engaging in real-world exercises, role-playing activities, and in-depth case studies, you will enhance your grasp of auditing concepts while gaining the confidence to implement them successfully in any environment. |

PrerequisitesThere are no required prerequisites for this training. This ISO 9001 lead auditor training course is beneficial for both quality novices and lifetime professionals. All students are required to bring their own printed copy of the ISO 9001:2015 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

The Certificate of Attainment provides evidence of knowledge competency defined by Exemplar Global for certification as a Quality Management Systems Lead Auditor.

Even though ISO 9001 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard.

Successful completion of this course’s examinations satisfies the training requirements for certification by Exemplar Global as a lead auditor.

| In-Person ISO 9001 Lead Auditor Training | AS9100D Lead Auditor Training | ISO 13485 Lead Auditor Training | Root Cause Analysis & Corrective Action Training |

OverviewIn today’s fast-paced business environment, organizations must ensure compliance with ISO 9001:2015 to maintain quality, enhance efficiency, and stay competitive. Effective auditing is the backbone of a strong Quality Management System (QMS), and skilled lead auditors play a critical role in driving continuous improvement. This interactive, in-person ISO 9001:2015 Lead Auditor Training equips you with the knowledge and practical skills to conduct, manage, and lead audits with confidence. Recognized by Exemplar Global, this course prepares you to interpret ISO 9001 requirements, assess compliance, and drive meaningful improvements in any organization. Guided by expert instructors, you’ll explore every phase of the audit process, including:

Through hands-on workshops, case studies, and real-world scenarios, you’ll develop the confidence to lead audits effectively, regardless of your industry or experience level. |

Topics Covered

|

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

The Certificate of Attainment provides evidence of knowledge competency defined by Exemplar Global for certification as a Quality Management Systems Lead Auditor.

Even though ISO 9001 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard.

Successful completion of this course’s examinations satisfies the training requirements for certification by Exemplar Global as a lead auditor.

| ISO 9001:2015 Internal Auditor Training | AS9100D Lead Auditor Training | ISO 13485 Lead Auditor Training | Root Cause Analysis & Corrective Action Training |

ISO 9001 Internal Auditor OverviewIn today’s competitive manufacturing industry, maintaining compliance with ISO 9001 is essential for ensuring product quality, meeting customer expectations, and driving continuous improvement. A strong Quality Management System (QMS) depends on effective internal audits, making skilled internal auditors a valuable asset to any organization. This interactive, live-online ISO 9001 auditor training provides you with the knowledge and tools needed to perform and participate in effective audits in accordance with ISO 9001:2015. Recognized by Exemplar Global, this ISO 9001 Internal auditor course prepares you to interpret ISO 9001 requirements, assess compliance, and drive meaningful improvements in any organization, all from the convenience of your home or office. Taught by experienced instructors in a dynamic virtual classroom, this course covers all key stages of the internal audit process, including:

You’ll also receive practical tools to simplify the auditing process, ensuring success regardless of your experience level or career stage. This engaging ISO 9001 internal auditor training combines real-world exercises, virtual role-playing scenarios, and interactive discussions to reinforce your understanding of audit principles. By the end of the course, you’ll have the confidence and skills to conduct internal audits that strengthen your QMS and contribute to organizational success. |

Topics Covered

|

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this course receive a Certificate of Attainment for these Exemplar Global (RABQSA) knowledge competency units: |

|

The Certificate of Attainment provides evidence of knowledge competency defined by Exemplar Global (RABQSA International) for certification as a Quality Management Systems Auditor.

Even though ISO 9001 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard.

| ISO 9001 Lead Auditor Training | AS9100D Lead Auditor Training | ISO 13485 Lead Auditor Training | Root Cause Analysis & Corrective Action Training |

ISO 9001 Internal Auditor OverviewAchieving and maintaining ISO 9001 certification isn’t just about compliance—it’s about building a culture of quality, improving efficiency, and staying competitive in today’s manufacturing landscape. ISO 9001 Internal auditors play a crucial role in identifying risks, uncovering opportunities for improvement, and ensuring that processes align with both customer expectations and industry standards. To conduct these audits effectively, organizations need well-trained internal auditors who understand how to assess compliance and drive meaningful change. This in-person ISO 9001 Internal Auditor Training provides a hands-on, interactive learning experience designed to equip you with the skills and confidence to conduct thorough audits. Recognized by Exemplar Global, this course teaches you how to interpret ISO 9001:2015 requirements, assess compliance, and drive meaningful improvements within your organization. Guided by expert instructors in a collaborative classroom environment, you’ll gain practical experience with every stage of the internal audit process, including:

The benefits of in-person ISO 9001 Internal Auditor training go beyond just learning the material. This format allows for direct engagement with instructors, real-time feedback, and valuable discussions with peers. Through group exercises, role-playing scenarios, and hands-on practice, you’ll refine your auditing skills in a way that online courses simply can’t match. By the end of this training, you’ll be well-prepared to conduct internal audits that strengthen your QMS, enhance compliance, and contribute to your organization’s overall success. Whether you’re new to auditing or looking to sharpen your skills, this immersive course ensures you leave with practical knowledge and the confidence to apply it immediately. |

Topics Covered

|

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this course receive a Certificate of Attainment for these Exemplar Global (RABQSA) knowledge competency units: |

|

The Certificate of Attainment provides evidence of knowledge competency defined by Exemplar Global (RABQSA International) for certification as a Quality Management Systems Auditor.

Even though ISO 9001 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard.

| ISO 9001 Lead Auditor Training | AS9100D Lead Auditor Training | ISO 13485 Lead Auditor Training | Root Cause Analysis & Corrective Action Training |

OverviewThe automotive industry demands rigorous quality standards, and organizations certified to IATF 16949:2016 must ensure their auditors are prepared to meet those expectations. Effective auditing is essential for maintaining compliance, managing risk, and driving performance across the supply chain. This dynamic, five-day live-online ISO 9001 & IATF 16949 Lead Auditor Training prepares you to conduct, manage, and lead audits to both standards with confidence. Recognized by Exemplar Global, the course covers key requirements of ISO 9001:2015 and IATF 16949:2016, including Core Tools and Customer-Specific Requirements, while aligning with ISO 19011 audit guidelines. Led by experienced instructors, you’ll explore each phase of the audit process, including:

Through interactive exercises, case studies, and role-playing scenarios, you’ll build the skills and confidence needed to perform high-value audits in automotive and manufacturing environments, all from the convenience of a live-online setting. |

PrerequisitesThere are no required prerequisites for this training. This ISO 9001 & IATF 16949 lead auditor training course is beneficial for both quality novices and lifetime professionals. All students are required to bring their own printed copy of the ISO 9001:2015 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

The Certificate of Attainment provides evidence of knowledge competency defined by Exemplar Global for certification as a Quality Management Systems Lead Auditor.

Even though ISO 9001 is used as the model for teaching systems and audit, this course enables students to develop and apply auditing skills using any applicable management system standard.

Successful completion of this course’s examinations satisfies the training requirements for certification by Exemplar Global as a lead auditor.

| In-Person ISO 9001 Lead Auditor Training | IATF 16949 & ISO 9001 Internal Auditor Training | IATF 16949 Lead Auditor (TS 16949) Training | Automotive Core Tools Training |

OverviewIn today’s competitive business environment, a strong internal audit program is essential for maintaining ISO 9001 certification, improving operational efficiency, and driving continuous improvement. Skilled internal auditors help organizations stay compliant, identify risks, and uncover opportunities for growth. This two-day, live-online ISO 9001 Internal Auditor training course is a great option for anyone who needs a quick, effective introduction to internal auditing or a focused refresher on the standard. Whether you’re new to ISO 9001 or looking to sharpen your skills, you’ll gain the tools and knowledge to plan, conduct, and report internal audits with confidence. Led by experienced instructors, you’ll cover every stage of the internal audit process, including:

The ISO 9001 internal auditor training course is delivered entirely online in a live, instructor-led format, providing flexibility and convenience without sacrificing interactivity or engagement. The training focuses on practical application rather than academic theory. Through case studies, hands-on activities, and realistic audit scenarios, you’ll gain real-world experience that reinforces your learning and prepares you to contribute immediately to your organization’s audit program. |

Pre-RequisitesThere are no required prerequisites for this training. This ISO 9001 Internal Auditor training course is beneficial for both quality novices and lifetime professionals. All students are required to bring their own printed or virtual copy of the ISO 9001 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| ISO 9001 Lead Auditor Training | AS9100 Lead Auditor Training | Root Cause Analysis & CAPA Training | ISO 13485 Lead Auditor Training |

OverviewIn the highly regulated medical device industry, ensuring compliance with ISO 13485 and FDA requirements is essential for maintaining quality, meeting customer expectations, and achieving market success. Effective auditing is a cornerstone of a strong Quality Management System (QMS), and skilled auditors are vital for helping organizations navigate complex regulatory landscapes. This interactive, live-online ISO 13485 Lead Auditor Training course provides the knowledge and practical skills needed to conduct QMS audits in accordance with ISO 13485:2016 and 21 CFR 820. Recognized by Exemplar Global, this course prepares you to interpret the standard’s requirements and apply them to your own organization, ensuring compliance with both international and U.S. regulations. Guided by expert instructors, you’ll explore every phase of the audit process, including:

This practical, hands-on ISO 13485 lead auditor training course goes beyond theory, using case studies, role-playing, and interactive exercises to build real-world auditing competence. By the end of the training, you’ll have the confidence and expertise to conduct internal, supplier, and third-party audits, helping your organization maintain compliance and drive continuous improvement. |

PrerequisitesThere are no required prerequisites for this training. This ISO 13845 lead auditor training course is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own printed copy of the ISO 13485:2016 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this ISO 13485 lead auditor training course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

This course is recognized by Exemplar Global as meeting the knowledge requirements for Lead Auditor Certification in Medical Device Quality Management Systems.

OverviewCompliance with ISO 13485 and FDA regulations is critical for medical device manufacturers to ensure product quality, meet customer expectations, and maintain regulatory approval. A well-executed audit program is essential for identifying risks, improving processes, and demonstrating compliance. Skilled lead auditors play a crucial role in helping organizations uphold these standards and achieve long-term success. This in-person ISO 13485 Lead Auditor Training course provides a structured, hands-on approach to auditing Medical Device Quality Management Systems (QMS). Recognized by Exemplar Global, this program equips participants with the knowledge and practical skills to conduct audits in alignment with ISO 13485:2016 and 21 CFR 820. Through real-world applications, you’ll learn how to interpret and apply the standard’s requirements within your organization. Led by experienced instructors, this course covers every stage of the audit process, including:

This ISO 13485 Lead Auditor in-person training experience provides direct interaction with instructors and peers, fostering deeper discussions, immediate feedback, and a more immersive learning environment. Hands-on exercises, role-playing scenarios, and case studies reinforce key auditing techniques, ensuring you leave the course with practical, applicable skills. By the end of the program, you’ll be prepared to conduct internal, supplier, and third-party audits with confidence, helping your organization maintain compliance and drive continuous improvement. |

PrerequisitesThere are no required prerequisites for this training. This ISO 13845 lead auditor training course is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own printed copy of the ISO 13485:2016 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this ISO 13485 lead auditor training course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

This course is recognized by Exemplar Global as meeting the knowledge requirements for ISO 13485 Lead Auditor Certification in Medical Device Quality Management Systems.

OverviewIn the highly regulated medical device industry, maintaining compliance with ISO 13485 and FDA requirements is essential for ensuring product quality, meeting customer expectations, and achieving regulatory approval. Internal auditing plays a critical role in sustaining an effective Quality Management System (QMS), and well-trained auditors are key to identifying risks, ensuring compliance, and driving continuous improvement. This interactive, live-online ISO 13485 course for Internal Auditor training provides the essential knowledge and hands-on skills needed to conduct internal audits in accordance with ISO 13485:2016 and 21 CFR 820. Recognized by Exemplar Global, this training equips you with practical auditing techniques and a deep understanding of the standard’s requirements, so that you can apply them effectively within your organization. Led by expert instructors, you’ll gain insight into every stage of the internal audit process, including:

This course goes beyond theory and uses real-world case studies, role-playing exercises, and interactive discussions to build confidence and competence in auditing. By the end of the training, you’ll be prepared to conduct internal and supplier audits as well as help your organization maintain compliance and improve its QMS. |

PrerequisitesThere are no required prerequisites for this training. This ISO 13845 course for internal auditor training is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own printed copy of the ISO 13485:2016 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this ISO 13485 course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

This ISO 13485 course is recognized by Exemplar Global as meeting the knowledge requirements for Internal Auditor Certification in Medical Device Quality Management Systems.

OverviewIn the highly regulated medical device industry, ensuring compliance with ISO 13485 and FDA requirements is essential for maintaining quality, meeting customer expectations, and achieving market success. Internal auditing is a critical function that helps organizations identify risks and drive continuous improvement. This in-person ISO 13485 Internal Auditor Training provides an immersive, face-to-face learning environment where you can engage directly with expert instructors and industry peers. Unlike online training, this in-person format allows for real-time feedback, hands-on exercises, and collaborative discussions, ensuring you leave with the confidence and competence to conduct internal audits effectively. Recognized by Exemplar Global, this immersive training experience ensures you leave with practical auditing techniques and a deep understanding of the standard’s requirements, so that you can immediately apply them in your organization. Led by expert instructors, you’ll gain insight into every stage of the internal audit process, including:

With case studies, group exercises, and audit role-playing, you’ll gain practical experience that you simply can’t get from a virtual classroom. The face-to-face setting fosters deeper engagement, encourages networking with other quality professionals, and ensures you receive immediate, personalized guidance tailored to your needs. |

PrerequisitesThere are no required prerequisites for this training. This ISO 13845 course for internal auditor training is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own printed copy of the ISO 13485:2016 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Global Certified Training Provider.

Attendees successfully completing the examinations provided in conjunction with this ISO 13485 course receive a Certificate of Attainment for these Exemplar Global knowledge competency units: |

|

This ISO 13485 course is recognized by Exemplar Global as meeting the knowledge requirements for Internal Auditor Certification in Medical Device Quality Management Systems.

OverviewISO 13485 is the internationally recognized standard for quality management in the medical device industry. Developed by the International Organization for Standardization (ISO), this standard ensures that medical devices are safe, effective, and meet the needs of patients and end-users. Compliance with ISO 13485 not only demonstrates your organization’s commitment to quality and safety but also helps you:

But how confident are you in your understanding of this critical standard? Can you effectively apply it to your organization’s Quality Management System (QMS)? This ISO 13485 Internal Auditor training course equips you with the knowledge and skills to perform internal audits with confidence. You’ll learn industry-proven techniques and gain practical insights into applying the ISO 13485:2016 standard to real-world audit scenarios. The course covers the full audit process, including tools and preparation, opening meetings, interviews, closing meetings, and reporting, ensuring you have a comprehensive understanding of quality system auditing. Whether you’re new to the quality field, expanding your expertise, or a seasoned professional, this course is designed to meet your needs. It provides foundational knowledge for beginners, advanced insights for experienced practitioners, and the latest best practices for industry veterans. In this interactive, live-online course, our expert instructors emphasize practical application, using hands-on activities and case studies to reinforce your understanding of ISO 13485 requirements. You’ll leave the course with the skills and confidence to drive quality and compliance within your organization. |

Pre-RequisitesThere are no required prerequisites for this training. This ISO 13485 Internal Auditor training course is beneficial for both quality novices and lifetime professionals. All attendees are required to bring their own copy of the ISO 13485:2016 Quality Management Standard Requirements to this training course. These will not be provided for you. We strongly advise you bring a paper copy or an electronic copy that allows you to take notes. |

|

Who Should Attend

|

OverviewThe 2024 revision of FDA 21 CFR Part 820 marks a major shift in medical device quality system requirements, aligning more closely with ISO 13485:2016 through the new Quality Management System Regulation (QMSR). Understanding these changes is essential for maintaining compliance and avoiding costly delays as the 2026 enforcement deadline approaches. QMSR applies to all FDA-regulated medical device manufacturers and introduces key updates that impact quality planning, documentation, audits, and risk management. It also reinforces the role of programs like MDSAP in supporting FDA compliance efforts. This focused, half-day, live-online FDA 21 CFR Part 820 training delivers exactly what busy professionals need: a clear, practical overview of the new requirements and what they mean for your organization. You’ll learn what’s changing, what’s staying, and how to begin planning your transition immediately—with real examples and actionable guidance you can apply the same day. Whether you’re in quality, regulatory affairs, or executive leadership, this course will help you stay compliant, reduce risk, and move forward with confidence. |

What You’ll Learn

|

|

Who Should Attend

|

Participants will receive a cGMP 2024 Revision: FDA 21 CFR Part 820 QMSR Implementation training certificate.

OverviewIn the complex world of medical device regulation, understanding and complying with the EU Medical Device Regulation (MDR 2017/745) is essential for maintaining product quality, ensuring patient safety, and achieving market access in the European Union. Manufacturers must navigate new requirements for technical documentation, risk management, device classification, and post-market surveillance, making MDR compliance both challenging and critical. This live-online EU MDR Training for Medical Device Manufacturers provides an interactive, instructor-led learning experience where you can engage in real-time with expert instructors and industry peers. Unlike self-paced courses, this format allows for live discussions, Q&A sessions, and collaborative exercises, giving you the confidence and competence to apply MDR requirements effectively in your organization. Recognized by Exemplar Global, this course equips you with the knowledge, tools, and strategies needed to navigate MDR compliance, including:

Through daily quizzes, practical tools, and interactive workshops on device classification, compliance scenarios, and real-world implementation examples, you’ll gain actionable skills that can be applied immediately. The live-online format fosters collaboration with other quality and regulatory professionals and ensures personalized guidance from expert instructors. By the end of this training, you will leave with the confidence to lead your organization toward MDR compliance, navigate complex regulatory requirements, and avoid common pitfalls, all while earning a registered Exemplar Global certificate that validates your mastery of the course material. |

Quizzes, Tools, WorkshopsThis is not a sit-and-listen course, and you will actively apply what you learn every day. Short quizzes help you confirm your understanding of key MDR concepts, while hands-on reviews of essential tools guide you through practical compliance steps. You will explore resources such as the EU MDR Gap Analysis Checklist, GSPR Conformity Checklist, Technical Documentation Checklist, and comparison tools for ISO 13485:2016 and ISO 14971:2012 requirements. To bring it all together, you will take part in interactive workshops focused on Device Classification, Compliance Scenarios, and real-world implementation exercises. You will leave ready to apply MDR principles in your own organization. |

|

Who Should Attend

|

| This class is certified by Exemplar Global under their Exemplify process. Accordingly, all students who attend the entire class, pass the quizzes, and demonstrate mastery of the workshops will receive a registered Certificate recognized by Exemplar Global. |  |

| ISO 13485 Lead Auditor Training | cGMP 2024 Revision: FDA 21 CFR Part 820 QMSR Implementation Training | Medical Device Single Audit Program (MDSAP) Training | ISO 14971 Training |

OverviewMedical device companies face growing pressure to comply with multiple regulatory systems across different countries. The Medical Device Single Audit Program (MDSAP) streamlines this process by allowing one audit to satisfy the requirements of participating markets, including the U.S., Canada, Japan, Brazil, and Australia. But to fully benefit from MDSAP, organizations need qualified internal auditors who can apply the model effectively and drive meaningful quality improvements. That’s where this training comes in. This training course is certified by Exemplar Global and gives you the tools and skills to audit Quality Management Systems in alignment with MDSAP and ISO 13485. Taught live-online over three days, this interactive course is designed for professionals at all experience levels. Through practical exercises and real-world case studies, you’ll learn to conduct effective audits using the audit model. You’ll follow the complete audit process, from planning and preparation to closing meetings and reporting, while developing the confidence to interpret and apply requirements in real audit scenarios. Rather than focusing on theory, this course emphasizes hands-on learning. You’ll gain practical techniques for conducting interviews, identifying audit evidence, and uncovering opportunities for true quality system improvement. Whether you’re responsible for audits, preparing for MDSAP certification, or supporting your organization’s compliance efforts, this course equips you to perform internal audits that add value. |

PrerequisitesThere are no required prerequisites for this training, though familiarity with ISO, US, Australia, Brazil, Canada, and Japan quality system requirements for medical devices is helpful. This MDSAP training is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own printed copy of the ISO 13485:2016 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Recognized Training Provider.

This MDSAP training course is certified by Exemplar Global, and upon completion, participants will receive a certificate that says they have successfully completed a course certified by Exemplar Global. |

|

| ISO 13485 Lead Auditor Training | cGMP 2024 Revision: FDA 21 CFR Part 820 QMSR Implementation Training | ISO 14971 Training | EU Medical Device Regulation (EU MDR) Training |

OverviewMedical device companies face increasing pressure to comply with multiple regulatory systems worldwide. The Medical Device Single Audit Program MDSAP helps streamline compliance by allowing one audit to meet the requirements of key markets, including the U.S., Canada, Japan, Brazil, and Australia. To take full advantage of MDSAP, organizations need highly skilled lead auditors who can manage audit teams, interpret requirements confidently, and deliver results that drive real quality improvements. This Exemplar Global–certified training course equips you with the knowledge, skills, and credentials to perform and lead audits of Quality Management Systems against MDSAP and ISO 13485 requirements. Delivered live-online over four days, the course combines expert instruction with interactive learning to prepare professionals to take on the responsibilities of a lead auditor. Through practical exercises, roleplay, and real-world case studies, you’ll gain hands-on experience in planning, conducting, reporting, and following up on audits. You’ll also develop advanced competencies in leading audit teams, managing communication with auditees, and making sound decisions about nonconformities. Rather than focusing solely on theory, this course emphasizes applied learning. You’ll practice techniques for conducting interviews, analyzing evidence, grading nonconformities, and writing clear nonconformity statements, all while simulating the full audit process. Whether you’re preparing for MDSAP certification, leading compliance efforts, or expanding your career as a professional auditor, this training provides the foundation and confidence to perform effective, value-added audits as a certified lead auditor. |

PrerequisitesThere are no required prerequisites for this training, though familiarity with ISO, US, Australia, Brazil, Canada, and Japan quality system requirements for medical devices is helpful. This MDSAP training is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students are required to bring their own printed copy of the ISO 13485:2016 standard. This will not be provided by Axeon, but most students will be able to obtain a copy from their company. |

|

Who Should Attend

|

| Axeon is an Exemplar Recognized Training Provider.

This MDSAP training course is certified by Exemplar Global, and upon completion, participants will receive a certificate that says they have successfully completed a course certified by Exemplar Global. |

|

| ISO 13485 Lead Auditor Training | cGMP 2024 Revision: FDA 21 CFR Part 820 QMSR Implementation Training | ISO 14971 Training | EU Medical Device Regulation (EU MDR) Training |

OverviewEffectively managing risk is essential to ensuring the safety, performance, and compliance of medical devices. ISO 14971 outlines the international standard for medical device risk management, and understanding how to apply it is critical for organizations across the industry. This live-online ISO 14971 training course is certified by Exemplar Global and offers a practical, hands-on approach to implementing risk management using ISO 14971:2019 and ISO/TR 24971:2020. Over two interactive days, participants will explore how to identify hazards, evaluate risk, implement controls, and maintain a comprehensive risk management process throughout the product lifecycle. Whether you are new to risk management or looking to deepen your expertise, this course is designed to meet you at your current level and build your confidence through expert instruction and real-world case studies. By the end of the course, participants will be able to:

Risk isn’t optional, and neither is compliance. This ISO 14971 training gives you more than a theoretical understanding of ISO 14971. It empowers you with practical skills that you can apply immediately in your role to reduce risk, improve product safety, and support regulatory readiness. Whether you’re preparing for audits, contributing to design decisions, or building risk files, this training will help you do it with confidence and credibility. |

PrerequisitesThere are no required prerequisites for this training. This ISO 14971 training is beneficial for both quality novices and lifetime professionals. Our goal is to meet everyone at their current level of competence and improve it. All students should bring their own printed copy of the ISO 14971:2019 and ISO/TR 24971:2020 standards. The course provides an overview of these documents, but having your own copy to follow along with will be a powerful learning aid. |

|

Who Should Attend

|

| Axeon is an Exemplar Recognized Training Provider.

This ISO 14971 training course is certified by Exemplar Global, and upon completion, participants will receive a certificate that says they have successfully completed a course certified by Exemplar Global. |

|

OverviewWhen a single failure can ground a fleet or compromise safety, aerospace manufacturers must get risk management right the first time. AS13004 offers a proven, structured approach to identifying and controlling process risks before they result in costly nonconformities, escapes, or customer dissatisfaction. This focused, two-day AS13004 PFMEA Risk Management Training equips aerospace professionals with the tools and methods needed to identify, assess, and mitigate risk throughout the production process. This course directly supports compliance with AS9100, AS9120, and AS13004 by focusing on the practical application of PFMEA and Control Plan development as key elements of a proactive risk management strategy. Led by instructors with deep industry experience, this course covers:

Through case studies, interactive exercises, and detailed walkthroughs, participants will gain hands-on experience developing PFMEAs and Control Plans that reduce variability, improve product safety, and strengthen compliance across the aerospace supply chain. |

What You Will Learn

|

|

Who Should Attend

|

OverviewIn the aerospace industry, effective problem-solving is critical to ensuring product quality, customer satisfaction, and long-term supplier relationships. Suppliers to top OEMs are required to have trained 8-D practitioners to lead robust corrective and preventive actions. The AS13000 Training (8-D): Root Cause & Corrective Action for Aerospace equips participants with the standardized skills and tools needed to meet this essential requirement. This two-day live-online course provides a comprehensive, hands-on approach to the AS13000 standard, which defines problem-solving requirements for the aero-engine sector. Using the Eight Disciplines (8D) methodology as its foundation, the course covers each discipline in detail and emphasizes practical application through real-world case studies. Participants will learn to identify root causes, implement effective corrective actions, and reduce the risk of problem recurrence, helping to minimize costs associated with poor quality and support a culture of zero defects. Led by experienced instructors, the course includes interactive exercises that develop skills in team dynamics, stakeholder management, and problem-solving tool application. Students will practice completing AS13000 8-D templates, leading problem-solving activities, and applying proven techniques such as Fishbone (Ishikawa) analysis, 5W2H, Pareto analysis, and control charts. By the end of this training, participants will be prepared to lead and facilitate 8-D problem-solving activities that meet AS13000 requirements. They will gain the knowledge, confidence, and practical skills necessary to strengthen corrective action processes, improve quality outcomes, and maintain compliance with top OEM standards. |

What You Will Learn

|

|

Who Should Attend

|

| Root Cause Analysis & Corrective Action Training | AS9102 First Article Inspection Training | AS9100 Lead Auditor Training – Certified by Probitas | Supplier Audit Training |

OverviewCorrective and preventive action (CAPA) failures are among the most common—and most costly—issues cited by the FDA. For medical device and pharmaceutical companies, an ineffective CAPA system can trigger major compliance problems, regulatory scrutiny, and product risks. But when done right, CAPA in medical devices becomes a powerful driver of quality improvement and risk reduction. This practical, two-day live-online training equips you with the skills and tools to build and maintain a compliant, effective CAPA system in line with FDA 21 CFR and ISO 13485 requirements. Designed specifically for professionals in medical device and pharmaceutical industries, the course teaches you how to perform efficient root cause investigations and develop corrective actions that truly solve problems and prevent recurrence. Led by experts in medical device and pharma compliance, this course covers:

Whether you’re responding to complaints, audit findings, or internal quality events, you’ll leave this course with the confidence to manage CAPA in medical devices and pharmaceuticals with clarity, consistency, and compliance. |

Topics

|

|

Who Should Attend

|

OverviewMistakes happen and processes fail, but unresolved issues and recurring problems can lead to wasted resources, compliance risks, and operational inefficiencies. It’s important for organizations to have effective root cause analysis procedures in order to ensure that these issues are corrected and prevented in the future. To help organizations tackle these challenges, Axeon’s Root Cause Analysis & CAPA training provides a structured, 8-step approach to Root Cause Analysis (RCA), Corrective Action, and Preventive Action (CAPA). This course applies to any industry or organization looking to improve problem-solving effectiveness. It emphasizes proven methodologies for identifying root causes, implementing corrective actions, and preventing recurrence, all while ensuring compliance with quality management system requirements. Using industry-recognized tools such as Five Whys, Ishikawa diagrams, and Failure Modes and Effects Analysis (FMEA), this Root Cause Analysis & CAPA training course provides a practical framework for improving process reliability and sustaining long-term improvements. Available both online and in-person, this interactive course combines expert instruction with hands-on exercises and real-world case studies. Whether you’re new to corrective actions or looking to refine your approach, this training will equip you with the skills needed to drive meaningful improvements in your organization. |

Root Cause Analysis & CAPA Training Key Topics

|

|

Who Should Attend

|

OverviewIn today’s highly regulated life sciences industries, failing to properly validate processes or software can lead to costly recalls, regulatory scrutiny, and compromised product quality. Whether it’s a new medical device, pharmaceutical process, or automated system, organizations need robust validation programs to ensure safety, effectiveness, and compliance. The Software and Process Validation Training equips professionals with the practical knowledge and skills required to meet these critical requirements. This three-day live online course provides a comprehensive understanding of process and software validation across the Pharmaceutical, Medical Device, Biotech, Biopharmaceutical, and Cosmetic industries. You will learn how to design, plan, and execute validation programs that align with regulatory expectations from the FDA, ISO 13485, ISO 14971, and GHTF guidance. Through expert instruction, real-world case studies, and interactive exercises, participants will gain hands-on experience developing validation protocols, implementing IQ, OQ, and PQ, and maintaining validated systems over time. The course also covers software validation, including FDA guidance, the classic V Model, software requirements development, verification and validation testing, defect prevention, and validation of automated and COTS systems. Participants will complete exercises such as validation master planning, protocol development, process capability assessments, and software testing scenarios to reinforce learning. This class is certified by Exemplar Global, and participants who complete all sessions and exercises will receive a registered certificate recognized worldwide. With this training, you will gain the confidence and practical expertise to lead or support a compliant validation program, ensuring your processes and software consistently deliver safe, effective, and regulatory-compliant results. |

Topics Covered

|

|

Who Should Attend

|

| Axeon is an Exemplar Recognized Training Provider.

This Process & Software Validation training course is certified by Exemplar Global, and upon completion, participants will receive a certificate that says they have successfully completed a course certified by Exemplar Global. |

|

| ISO 13485 Lead Auditor Training | cGMP 2024 Revision: FDA 21 CFR Part 820 QMSR Implementation Training | ISO 14971 Training | EU Medical Device Regulation (EU MDR) Training |

OverviewThe transition to the In Vitro Diagnostic Regulation (IVDR 2017/746) marks a major shift for medical device manufacturers in the European market. Under the IVDR, all existing in vitro diagnostic devices must be recertified to meet new, more rigorous requirements. There are no grandfathering provisions, so understanding and implementing these changes is essential for continued market access and compliance. This live-online training for medical device manufacturers provides a comprehensive, hands-on look at the regulation and its practical application. You will explore the requirements’ structure, timelines, and paths to CE marking, along with the significant articles and annexes that impact manufacturers most. Through expert instruction, practical examples, and interactive workshops, you will gain the knowledge and tools to navigate the transition from IVDD to IVDR with confidence. Led by experienced instructors, this three-day course covers:

Recognized by Exemplar Global through their Exemplify process, this course awards a registered certificate to participants who complete all sessions, pass the quizzes, and demonstrate mastery of the workshops. By the end of this training, you will have a clear understanding of the requirements and the practical steps needed to achieve and maintain compliance. You will leave prepared to guide your organization through the transition with confidence and ensure continued access to the European market. |

Included DocumentsIn addition to a slide presentation, activities, and quizzes, this class includes the following documents for students to utilize in their positions:

|

|

Who Should Attend

|

| Axeon is an Exemplar Recognized Training Provider.

This IVDR training course is certified by Exemplar Global, and upon completion, participants will receive a certificate that says they have successfully completed a course certified by Exemplar Global. |

|

| ISO 13485 Lead Auditor Training | cGMP 2024 Revision: FDA 21 CFR Part 820 QMSR Implementation Training | ISO 14971 Training | EU Medical Device Regulation (EU MDR) Training |

OverviewIn the aerospace engine industry, delivering consistent, high-quality products isn’t just a competitive advantage. It’s a customer expectation. The AS13100 Revision A standard, released in April 2025, brings updated requirements to help suppliers streamline compliance across multiple OEMs while improving quality and reducing variation. Developed by the Aerospace Engine Supplier Quality (AESQ) Strategy Group, AS13100 harmonizes customer-specific requirements and translates them into a unified framework that suppliers can implement with clarity and consistency. The new revision includes important clarifications, expanded guidance on defect prevention, and updated expectations around measurement systems analysis, process control, and first article inspection. This interactive, live-online course is designed for aerospace suppliers looking to understand and implement the latest requirements and associated AESQ Reference Manuals (RMs). Whether you’re already certified to AS9100 or just beginning your journey, this training equips you with the knowledge and tools to integrate AS13100 into your QMS effectively. Led by experienced instructors, you’ll explore how AS13100 aligns with AS9100 and AS9145, with a strong emphasis on Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), and Core Quality Tools. You’ll also learn how to translate AS13100 into actionable requirements within your own organization and supply chain, ensuring compliance, improving audit readiness, and supporting long-term quality performance. |

TopicsAESQ AS9100 Supplemental Requirements for: Strategic Planning, Top Management, Competence & Awareness, Risk Management, Monitoring Equipment, Human Factors, Design & Development, Supply Chain Management & Control, Manufacturing Systems, Internal Audits, and Corrective Action AESQ AS9145 Supplemental Requirements for: APQP – Project Management, Design & Development, Process Design & Development, Validation of Products and Processes; PPAP – File Submission and Disposition, Supply Chain PPAPAESQ Core Defect Prevention Quality Tools: DFMEA, PFMEA, Key Characteristics, Process Flow Diagrams, Control Plans, MSA, Capability Studies |

|

Who Should Attend

|

| AS9100 Rev D Lead Auditor Training | AS5553 & AS6174 Counterfeit Parts Training | AS9102 First Article Inspection Training | AS9145 APQP & PPAP Training |

OverviewDeveloping a new product is a complex process that requires proactive planning, strong collaboration, and reliable controls to ensure quality from concept through delivery. Without the right structure in place, organizations face costly delays, supplier quality issues, and risks that can impact performance and customer satisfaction. Axeon’s AS9145 Advanced Product Quality Planning & Production Part Approval Process Training provides the framework needed to deliver aerospace products that meet requirements the first time. This course aligns with the AS9145 standard, which spans early concept development, design and process development, validation activities (PPAP), and post-delivery oversight. Participants will learn how these activities integrate with established aerospace quality standards, including AS9100, AS9102, AS9103, and AS9110. Through expert guidance and practical exercises, this two-day course helps teams enhance planning discipline, strengthen supplier management, and ensure product and process readiness before full-scale production. Attendees will gain a solid understanding of project phases, documentation requirements, approval expectations, and how to apply a risk-based approach throughout the product lifecycle. Delivered live in a virtual classroom environment, this instructor-led course includes hands-on workshops using industry tools such as SCMH checklists, real-world implementation examples, and a comprehensive case study. Whether you are overseeing production development, evaluating supplier readiness, or improving internal processes, this training equips you to reduce uncertainty, improve quality outcomes, and maintain compliance in today’s demanding aerospace environment. |