Fundamentals and Applications of Geometric Dimensioning & Tolerancing (GD&T) Training

Days: 3

7:30 AM- 4:30 PM MST

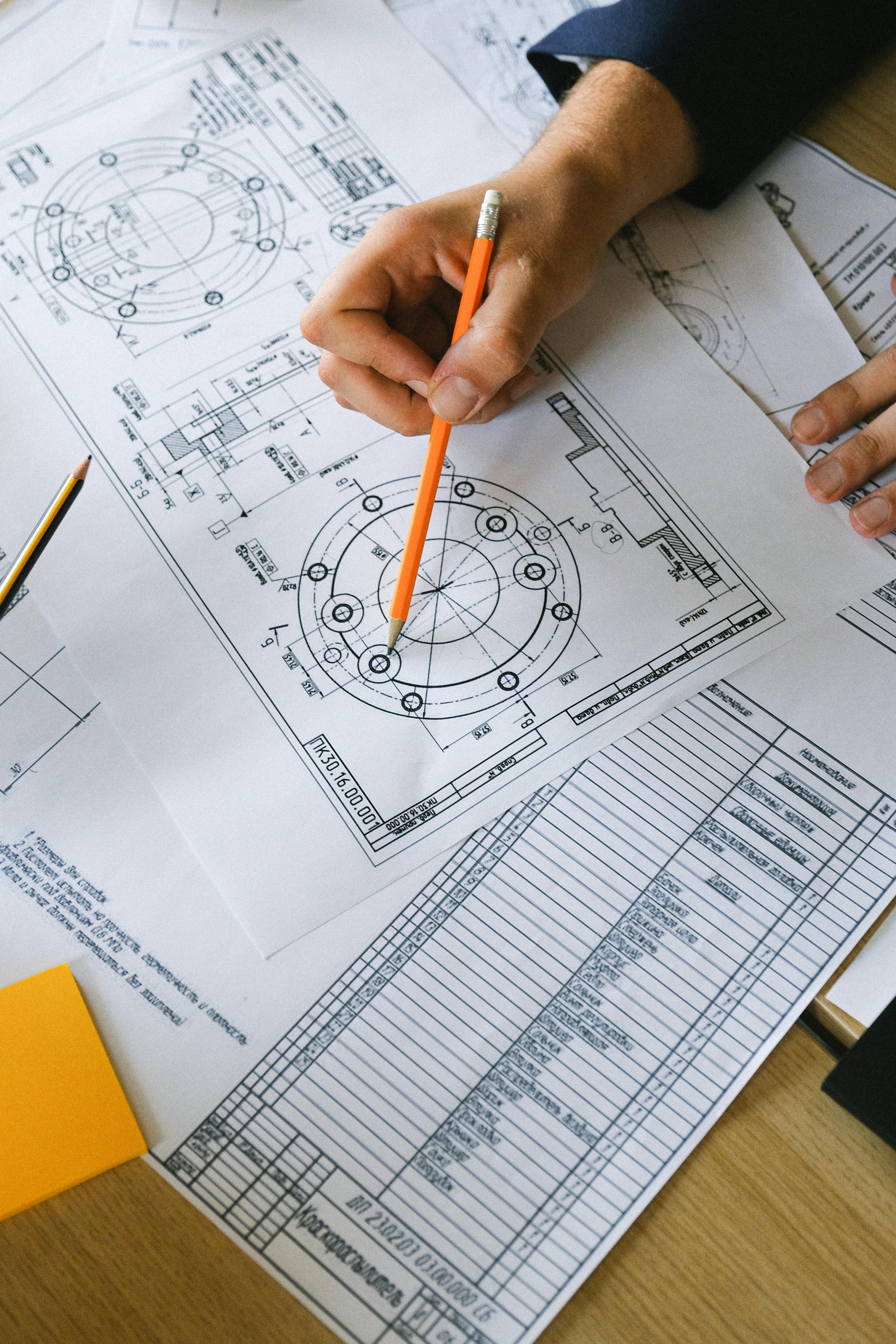

OverviewGeometric Dimensioning and Tolerancing (GD&T) is a powerful tool for improving communication, design clarity, and manufacturing efficiency. This three-day course provides a comprehensive, intermediate-level introduction to the ASME Y14.5 standard, giving participants the knowledge and practical skills needed to interpret, apply, and communicate GD&T effectively across design, manufacturing, and inspection processes. The course begins with the history and principles of Geometric Dimensioning and Tolerancing, demonstrating how it enhances design intent, ensures consistency across drawings, and facilitates collaboration between engineering, purchasing, and manufacturing teams. Participants will then explore frequently used geometric controls and tolerancing practices, with a focus on positions, datum reference frames, and feature control frames. Hands-on exercises reinforce real-world applications, helping attendees understand the advantages of GD&T in mechanical engineering and manufacturing workflows. By the end of the course, attendees will be able to read and apply Geometric Dimensioning and Tolerancing standards with confidence, make informed decisions when selecting tolerances, and improve part functionality, quality, and communication throughout the product lifecycle. |

PrerequisitesParticipants need to have a working understanding of technical drawings (perspectives, sections, details, etc) in order to be fully successful in this Geometric Dimensioning and Tolerancing training. Participants also need the ASME Y14.5-2018 Dimensioning and Tolerancing standard. This will not be supplied by Axeon. |

|

Who Should Attend

|

Geometric Dimensioning and Tolerancing Learning Objectives

- Review and understand the “old” system versus GD&T including terminology and basic rules.

- Understand the general rules of dimensioning and drafting per the standard.

- Understand the different Tolerance Zones and their definitions, concepts, and comparisons to existing systems.

- Understand and apply the symbology and definitions of controls.

- Utilize and understand the Datum Reference Frames and their definition as well as their proper construction and selections.

Agenda

Related Courses

| AS9100 Rev D Lead Auditor Training | ISO 9001 Lead Auditor Training | IATF 16949 Lead Auditor (TS 16949) Training | Statistical Process Control (SPC) Training |

Location

Location

Register

Register Login

Login